…Build Your own Uke at the Bailey workshop…

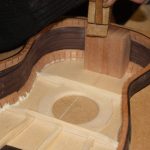

- Preparing the Rosette Channel

- Ellis is using white PVA to glue in the strips for her Rosette

- The Sound Hole

- Fitting the tone bars

- Carving the Braces

- Gluing the Back Braces

- Bending the Sides

- Bending the sides

- Gluing the kerfed lining

- The heel and tail blocks are glued

- Preparing to glue the Soundboard

- The sides are completed

- Gluing the soundboard

- Gluing the Soundboard

- Gluing the back

- The body is complete

- Dovetail mortice in the body

- The Mahogany neck is rough cut

- Completed neck joint

- Fretboard Inlays

- Fretboard Inlays

- A ‘clutch’ of Uke’s?

Ellis, Fiona, Jamie and Peter are currently building their first Ukuleles on our brand new Build Your Own Uke course. We are now four days in and it will take another day and a half to complete them. Once they are all finished we will be able to confirm exactly how long the course will be, but it looks like it will be at least 5 days ! This is a great introduction to acoustic instrument making. There are no kits here, and as you will be building completely from scratch, by hand, there are many opportunities to upgrade and customise for those who want to spend a little more. You can choose your own wood and hardware for instance and add a pickup if desired. The standard size will be Soprano with the option of different sizes which will also add extra cost. The girls are both making Concert Sized and the boys, Soprano. They are all using Indian Rosewood for the back and sides with Sitka Spruce for the soundboards, except Ellis who has chosen Cedar.

Don’t Forget!

We don’t just run courses…Have a look at our own unique range Uke’s all hand crafted here in the UK.

And Remember!

If you don’t see what you like we can build it for you – Contact us with your ideas.