Fitting the neck to the body with a dovetail joint

- Archtop guitar dovetail jig

- The dovetail slot in the body

- Archtop guitar dovetail front view

- Neck dovetail ‘test piece’

- The neck dovetail jig

- The ‘neck test piece’ is dovetailed

- The actual neck is machined

- A perfect fit

- Gluing the neck extension

- Close up of neck extension

- Ready to fit the truss rod

- Installing the truss rod

- Aligning the fretboard

- Rear view

- Ready to glue the fretboard

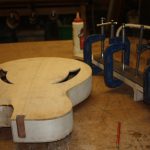

- Clamping the archtop guitar fretboard

- Gluing the ‘wings’ on the side of the headstock

- Custom headstock designed by Steve

- Rough carving the neck

- The neck is now roughly carved

Captains Log

Stardate : 05312.5

Today we passed a milestone in our continuing journey to go where no Jazz Archtop has gone before. It was my duty as captain to single handedly complete the first docking procedure with the new jazz class spaceship. It is necessary to ensure this runs smoothly as we do not want any issues to arise when the time comes to permanently attach the neck to the body.

The neck cannot be glued on until the guitar is just about finished during the final ‘docking procedure’, but the dovetail must be made before the fretboard is glued on or the neck would not fit into the jig.

Completing the neck joint is one of the major jobs when making an Archtop style guitar. It has to be a dovetail as there is no way to get hands inside the body to tighten any bolts.

This is also how the neck angle is set so that the strings will arrive at the right height for the bridge, and also the alignment- the centre of the neck must align with the centreline on the body.

The body mortice is cut first then the fitted neck to it, using a piece of ‘scrap’ to practice on until the angle and alignment is correct, then swapping it for the real neck to complete the dovetail joint.

After this I can glue the neck extension, install the truss rod and glue on the fretboard.

This headstock is going to be quite large so I added some ‘wings’ to each side to increase the width so the shape will fit on.

Steve designed his own headstock which I traced and marked out onto the wood before drilling the tuner holes and cutting out the shape.

Finally I rough carved the neck. I left it slightly oversized for now and will refine it after the frets are fitted. I may have to work on the fretboard first so it is good to leave a little leeway for this. Now I will let it settle for a while…

Contact us if you would like to commission your own epic custom build, or visit our online shop to see some ready made examples.